Why CAT C15, 3406E, and C18 Cylinder Heads Fail — Even When Everything Seems Fine

The Issue: OEM Heads and Heat Cycle Fatigue

Even without signs of overheating, OEM CAT cylinder heads often fail during standard heat cycles. The root cause lies in the metallurgy of the original castings, which lack the durability to withstand repeated thermal expansion and contraction. This leads to:

-

Stress fractures near injector bores and valve bridges

-

Warping across the fire deck

-

Internal coolant leaks

The Solution: High-Nickel Aftermarket Castings

At TTM Diesel, we offer aftermarket cylinder heads with 5% more nickel content than OEM specifications. This enhancement provides:

-

Improved thermal fatigue resistance

-

Reduced crack formation during heat cycles

-

Enhanced durability for high-performance applications

Engines Most Affected

| Engine Model | Common Issues |

|---|---|

| CAT 3406E | Fire deck cracks, valve bridge fractures |

| CAT C15 | Injector bore cracking, deck warping |

| CAT C15 ACERT | Twin turbo heat fatigue, cracked intake bridges |

| CAT C16 | Microfractures over time |

| CAT C18 | Cracks under load without overheating symptoms |

Image Placement Suggestions

-

Top of Article: High-resolution image of a cracked CAT cylinder head.

-

Mid-Article: Side-by-side comparison of OEM vs. high-nickel aftermarket head.

-

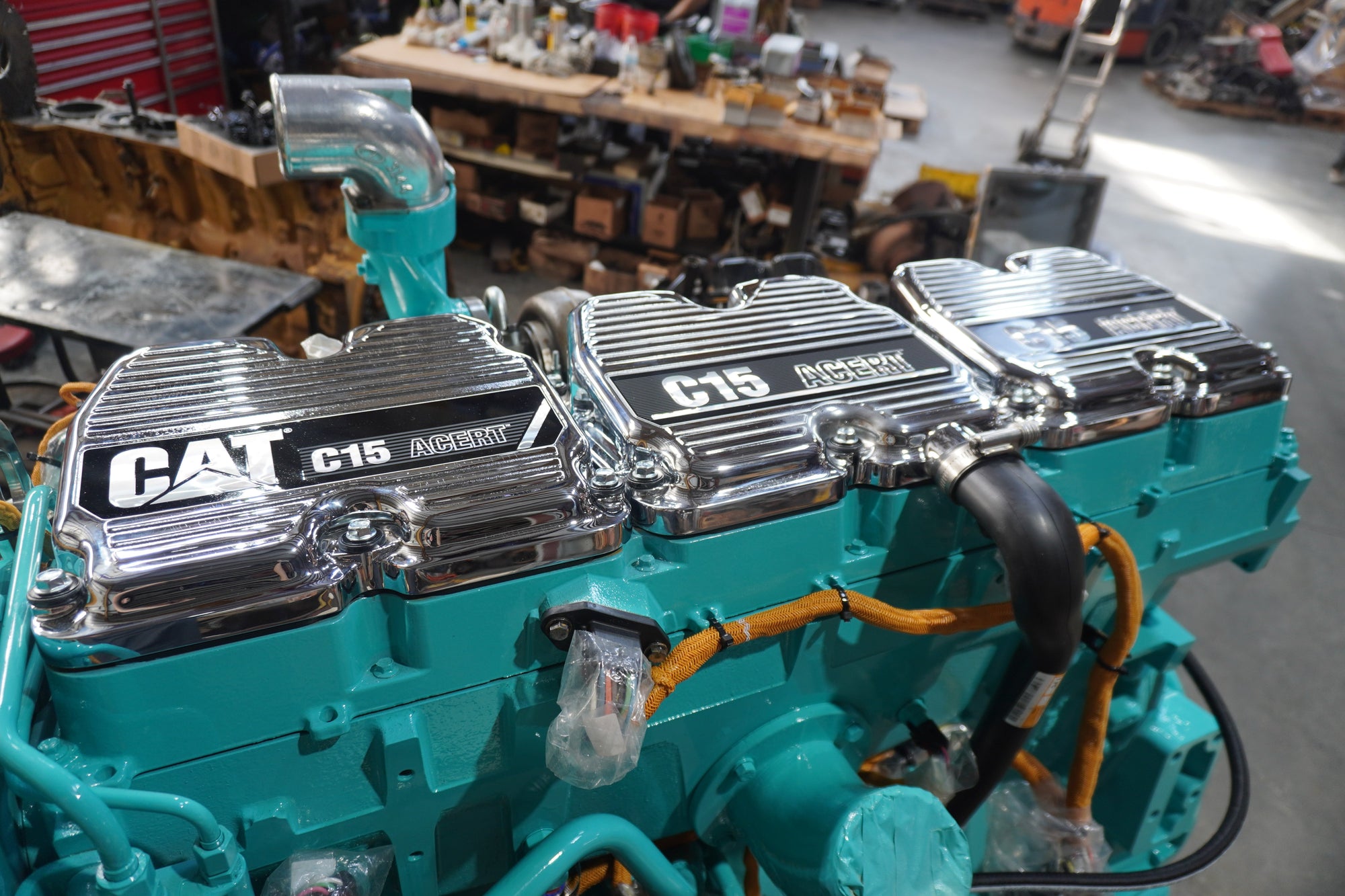

Bottom of Article: Image showcasing TTM Diesel's high-quality cylinder heads.

Need a Reliable CAT Cylinder Head?

TTM Diesel offers high-quality aftermarket cylinder heads for:

-

CAT 3406E

-

CAT C15 & C15 ACERT

-

CAT C16 & C18

-Pressure-tested and decked

-Assembled with precision

-Enhanced nickel content for durability

Browse Our CAT Cylinder Heads »

Or call us at (713) 675-2435 — we're here to help you get back on the road swiftly.